Capstone

Capstone: Preventing COVID-19 Transmission in Taxis and Rideshares

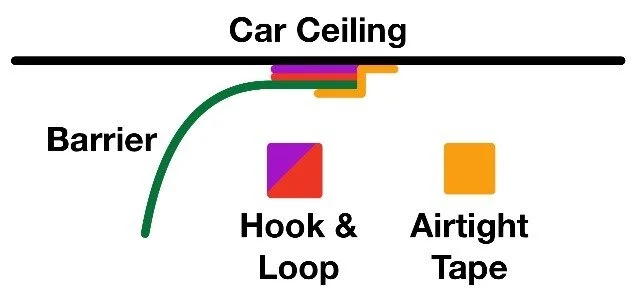

In the summer and fall of 2020, I worked with 4 other mechanical engineers on a capstone project to design and develop a system that would prevent COVID-19 transmission between the passenger and driver of a taxi or rideshare vehicle. In the late summer, we spent two months researching the virus and brainstorming solutions to this problem until we arrived at the design pictured on the right. This design incorporated a fully flexible plastic barrier that could be cut to fit into any mid-sized sedan and a HEPA filter assembly that would blow clean air from the front cabin to the rear seats. The barrier would be attached to the walls and ceiling with adhesive-backed hook-and-loop, which would then be sealed over the top with tape. We originally tried to incorporate a brace into the system to hold up the filtration assembly, but decided to simply attach it to the back of the passenger’s chair as it reduced the complexity of the system.

Original HEPA filter design

Revised Filtration Assembly Location

Barrier attachment method

Starting in September 2020, we began to simulate and test our design. We started by calculating how much air a car cycles in air changes per hour (ACH), and researched what a “safe” ACH would be. Hospital clean room guidelines recommend 12 ACH, so we based our design around that number. We then modeled a car and simulated this airflow in SolidWorks and Ansys to ensure that we would not create any pressure buildups or dead zones in the cabin.

After simulating our design, we began our first prototype testing, which is shown in a video below.